Poor Compressed Air Quality impacts Nitrogen Purity

- David De Pril

- Jul 17, 2025

- 2 min read

In many industrial applications, nitrogen generators—especially those based on Pressure Swing Adsorption (PSA) or Membrane technology—rely heavily on a consistent supply of clean, dry compressed air. One often overlooked but critical factor in this supply chain is the pressure dew point of the compressed air. A poor dew point, indicating high moisture content, can significantly degrade nitrogen purity and jeopardize the integrity of processes that depend on it.

Understanding Pressure Dew Point and Its Role

The pressure dew point is the temperature at which water vapor in the air begins to condense. In compressed air systems, a low enough but more importantly a stable dew point is desirable to ensure that moisture does not enter sensitive equipment like nitrogen generators.

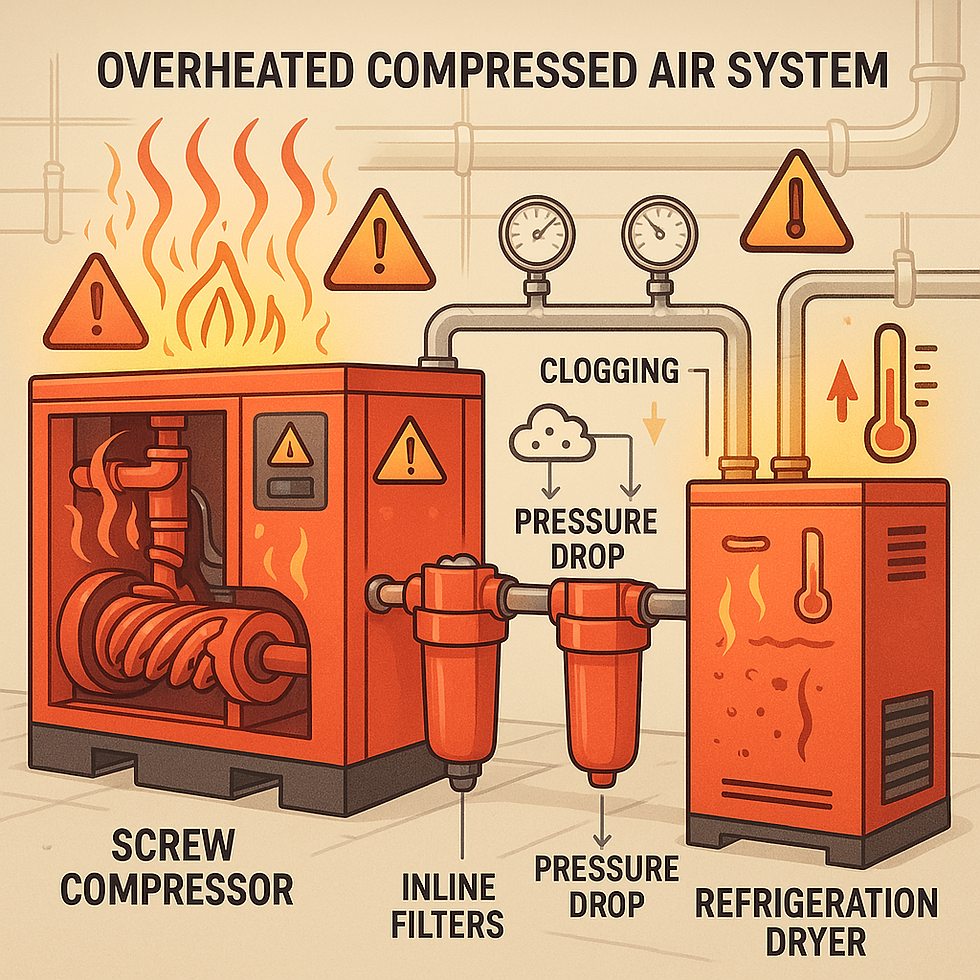

When the dew point is too high—often due to a malfunctioning or undersized fridge dryer—excess moisture enters the nitrogen generator. This can lead to:

Saturation of adsorbent materials in PSA systems (e.g., carbon molecular sieves)

Reduced membrane efficiency in membrane-based systems

Corrosion and fouling of internal components

Increased maintenance and downtime

Impact on Nitrogen Purity

Moisture in the feed air directly affects the selectivity and adsorption capacity of nitrogen generators. In PSA systems, water competes with oxygen during the adsorption process, reducing the system’s ability to separate nitrogen effectively. This results in:

Lower nitrogen purity (e.g., dropping from 99.999% to below 95%)

Fluctuating purity levels, which can be difficult to detect without continuous monitoring

Increased oxygen and moisture content in the nitrogen output

Consequences for Downstream Processes

The implications of compromised nitrogen purity vary depending on the application, but they can be severe:

1. Food and Beverage Industry

Oxidation of products due to residual oxygen

Spoilage and reduced shelf life

Regulatory non-compliance

2. Pharmaceutical Manufacturing

Contamination of sterile environments

Degradation of sensitive compounds

Batch rejection and financial loss

3. Electronics and Semiconductor Fabrication

Corrosion of components

Reduced yield and product reliability

Costly rework or scrapping of materials

4. Laser Cutting and Welding

Poor cut quality due to oxygen interference

Increased scrap and rework

Reduced throughput

Preventive Measures

To mitigate these risks, facilities should:

Monitor dew point continuously using reliable sensors

Choose compressors with low oil carry over and outlet temperatures

Maintain and service fridge dryers regularly

Use desiccant dryers when ultra-dry air is required to reach purity level

Install pre-filtration and coalescing filters to remove bulk water and oil

Install no loss drain valves to remove condensate at aftercooler, dryers, tanks filters and eventually pipework

Audit compressed air systems periodically for leaks and inefficiencies

Conclusion

The concept and maintenance of the entire system is important. Poor nitrogen purity isn't an option hence the selection of the installation components is crucial to mitigate the risk. Your productivity and profitability depends on this capital utility. Nitrogen is like process air, it has a direct contact and impact on the quality of your product, hence the end customer satisfaction. Reach out for more detailed risk mitigation and a peace of mind operation.

Comments