Hottest days of the year, time to do a check your compressed air quality

- David De Pril

- Jul 17, 2025

- 2 min read

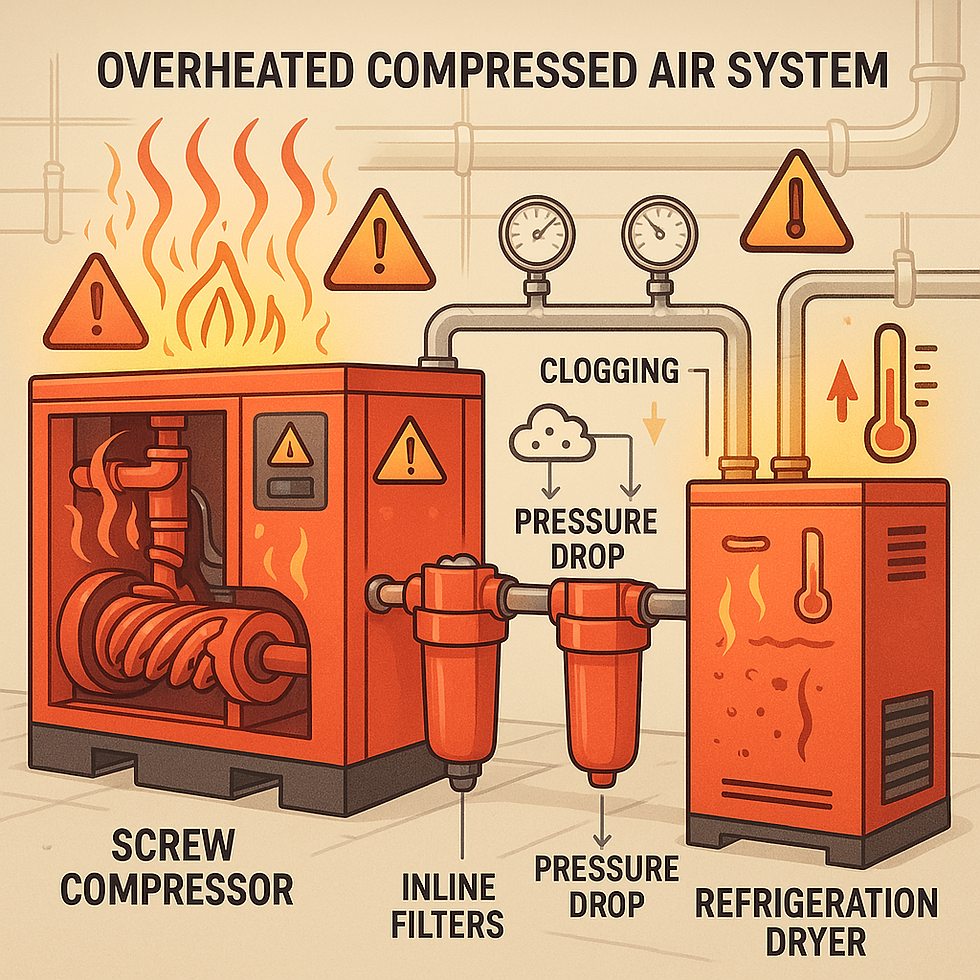

Lower the compressor energy consumption by doing maintenance: change filters, clean aftercooler, change oil etc. The lower the energy, the lower the heat generated, the lower the outlet temperature, the better for the dryers...

Compressors

Check inlet filter and replace if needed. This creates a vacuum at the inlet of your airend, hence the compressor differential pressure increases.

Replace your oil filters and change the oil. Clean oil circuit and oil quality is important to lower the compression temperature. Overheated oil will result into decomposition of the oil with a risk on increase wear and tear

Clean or replace oil separator elements. It's very important to keep the state of the element in good condition, it will assure the oil carry over level isn't increased

V-Belt or coupling rubber to be replaced if required. Check certainly the tensioning and the alignment for belt driven compressors

Regrease motor bearing (don't over grease though)

Clean all coolers to assure that they are free of dust. Cleaned coolers will reduce the stress on the oil and compressed air temperatures

Inline pre-filters:

Clean/replace inline and activated carbon filter elements.

Do make sure that your drains are working.

Clogged filters require your compressor to overcome a higher delta p for your application hence more heat generated.

Dryers:

Fridge dryers:

Clean condenser and drain valves. This should help to lower the pressure dew point... if not, your dryer isn't suitable for the summer conditions, or is undersized, or is composed of an undersized heat exchanger or it can't handle the flow variation in a cycling mode

Dessicant dryers:

Check the purge flow and/or regeneration method. When heated blower, do a blower maintenance. Check filters etc. For vacuum regenerated, maintain the vacuum pump.

Inline post-filters:

Make sure your downstream filtration is also looked after... humidity and dust will build up, resulting into a bad air quality at the application.

Room Ventilation:

Check your room ventilation filters. Ambient room temperature has to be as low as possible. Clean the filters so fresh air can enter and hot air can evacuate.

Oil Water Separators

Check and service the Oil Water Separators to protect the environment

Receiver Tanks

Check at least that the tanks are drained. If a time drain or a manual drain is installed, consider to replace it with a no loss drain

Conclusion:

It's all about common sense. Check the state of the overall system and do a preventive maintenance. It will safeguard your installation and eliminate the risk of temperature alarms or breakdowns.

Comments