Lowering compressed air pressure: positive and negative implications for air quality and system performance.

- David De Pril

- Jul 15, 2025

- 2 min read

Updated: Jul 17, 2025

✅ Potential Benefits of Lowering Compressed Air Pressure

Improved Energy Efficiency:

Lowering pressure reduces the energy required to compress air. For every 1 bar (14.5 psi) reduction, energy consumption can drop by about 7%.

Reduced Air Leaks:

Leaks are proportional to pressure. Lower pressure means less air lost through leaks, which improves overall system efficiency.

Less Wear and Tear:

Operating at lower pressures reduces mechanical stress on compressors, piping, and end-use equipment, potentially extending their lifespan.

⚠️ Pitfalls and Risks of Lowering Pressure

Insufficient Pressure for End-Use Equipment:

Many tools and machines require a minimum pressure to function correctly. Dropping below this threshold can lead to underperformance or shutdowns.

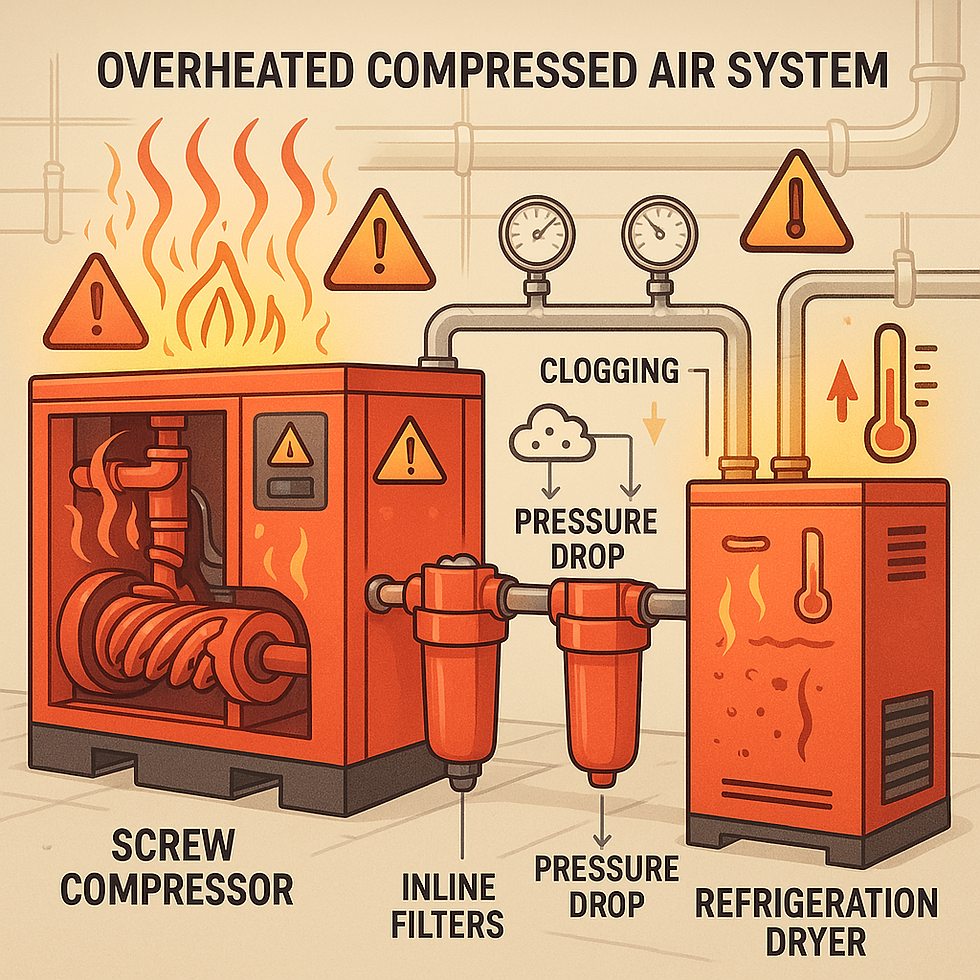

Air Quality Degradation:

Lower pressure can reduce the effectiveness of air dryers and filters, allowing more moisture, oil, or particulates to remain in the air stream.

Contaminants like water vapor and oil can damage seals, corrode pipes, and compromise product quality.

Increased Pressure Drop Sensitivity:

At lower system pressures, any pressure drop (from friction, bends, or dirty filters) becomes more significant relative to the total pressure, potentially affecting performance.

System Design Limitations:

Existing piping and components may not be optimized for lower pressure operation. For example, undersized pipes or long distances can cause excessive pressure drops.

🛠️ Best Practices to Mitigate Risks

Audit and Optimize System Design:

Ensure piping is appropriately sized and laid out to minimize friction and bends.

Use High-Efficiency Filters and Dryers:

Select components rated for lower pressure operation to maintain air quality.

Monitor and Maintain:

Regularly check for leaks, clean filters, and inspect for obstructions or corrosion.

Match Equipment to Pressure Needs:

Avoid using medium-pressure compressors for low-pressure applications. Instead, use dedicated low-pressure technologies like rotary screw or centrifugal blowers.

Comments